What Is A Hydraulic Cone Crusher? - HongXing

2019.12.5 A hydraulic cone crusher actually is a cone crusher adopting the method of adjusting the discharging port by the hydraulic

Read More

Sandvik Cone Crushers - SRP

Our crusher automation system delivers real-time performance management, enabling you to monitor and optimize crusher performance and productivity. The new Sandvik 800i is a series of tough, premium

Read More

Cone Crusher - an overview ScienceDirect Topics

The cone crusher is a modified gyratory crusher. The essential difference is that the shorter spindle of the cone crusher is not suspended, as in the gyratory, but is supported in a

Read More

HPY Multi-cylinder Hydraulic Crusher - Luoyang

2023.11.8 Application of Hydraulic Cone Crusher 1.For granite, quarry stones, rocks, aggregate, basalt, limestone, gold ore, iron ore, etc. 2.Common final output size:0-10mm, 10-20mm, 20-30mm, 30-40mm,

Read More

Sandvik CH660 Cone Crusher For Pebble-Crushing Applications

This cone crusher has a hydraulically supported main shaft that is supported at both ends. Sandvik CH660 has a robust crusher design, adjustable eccentric throw, and a constant

Read More

HAZEMAG CYBAS-i Cones High Performance Cone Crusher

2022.7.6 Cone Crusher is supported and controlled by a hydraulic system during operation. This type of crusher design is referred to as a hydroset design and boasts the

Read More

Sandvik® Hydrocone® Superior® Crushers parts - FLSmidth

Key benefits We offer cost effective Sandvik Hydrocone and Superior cone crushers parts Replacing parts is a drag on your business. Maintenance down time eats away at your

Read More

New comminution applications using hydrocone crushers

1996.3.1 The setting (distance between mantle and concave ring) of the Hydrocone cone crusher is altered, even with the crusher operating at full load, by lifting or lowering

Read More

(PDF) Cone Crusher Performance - ResearchGate

2015.5.13 In this thesis a method for prediction of cone crusher performance is presented. The model is based on the laws of mechanics and constitutive relations concerning rock breakage characteristics ...

Read More

Our Range of Trio® Cone Crushers Weir

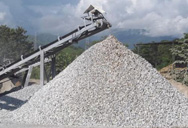

A cone crusher is a type of crusher that is commonly used for processing rocks in mining and aggregate applications. These crushers use compression force to break large rocks (and other materials) into smaller rocks, gravel and sand.. Since its inception, the live-shaft cone crusher design is highly regarded as the benchmark for reliable hard rock cone

Read More

McLanahan CMB Cone Crushers

Below are suggested speed guidelines for CMB Cone Crushers: Low speed: Secondary applications, after a Jaw Crusher. Medium speed: Gravel applications with coarse feed. Standard speed: Tertiary applications (0 x 1/2”) High speed: Sand applications (4m or less) Speed ranges: Smaller head diameters (48” or smaller): 750-1,200 rpm.

Read More

Sandvik® Hydrocone® Superior® Crushers parts - FLSmidth

We cover a wide range of cone crusher replacement parts for Sandvick cone crusher parts for Hydrocone and Superior Crushers, including the head center, arm shield, burning ring and more. In many cases, we have improved the design of the OEM spare parts to enhance durability and performance. From the older Allis-Chalmers® and Svedala® models ...

Read More

The pros and cons of cone crusher applications - Quarry

2021.4.16 A cone crusher in a secondary crushing application will typically work with a 3.5:1 to 5:1 reduction ratio. Tertiary cone crusher configurations typically work with a reduction ratio of 2.5:1 to 4:1. The reduction ratio is defined as the ratio of the feed size for which 80 per cent will pass (F80), divided by the product size for which 80 per ...

Read More

Industrial Solutions Kubria cone crushers - ThyssenKrupp

2022.11.21 Kubria® cone crusher (1,100 mm cone diameter) in a quartz porphyry works Feed grain size 5 – 32/44 mm Product size 0 – 22 mm Throughput approx. 150 t/h Kubria® cone crusher (2,100 mm cone diameter) for crushing granite Feed grain size 75 – 350 mm Product size 0 – 75 mm Throughput approx. 800 t/h Two Kubria® cone crushers

Read More

EXCEL™ Replacement parts for Allis-Chalmers® and

2023.9.12 certify our crusher bronze to the top end of the CDA specification for tin. Uniform lead distribution Porosity-free/uniform grain structure ... FLS — Replacement parts for Allis-Chalmers® Svedala® Hydrocone® Cone Crushers 3. Allis-Chalmers® Svedala® Hydrocone® Cone Crushers 22”, 36”, 45”, 51”, 60”, 72”, 84”, 500 ...

Read More

Gyratory Crushers - 911 Metallurgist

2016.2.17 Gyratory Crushers. The primary rock breaker most commonly used in large plants is the gyratory crusher, of which a typical section is shown in Fig. 5. It consists essentially of a gyrating crushing head (521) working inside a crushing bowl (522) which is fixed to the frame (501). The crushing head is carried on a short solid main shaft (515 ...

Read More

Gyratory Crusher (Gyratory Crushers Explained) - saVRee

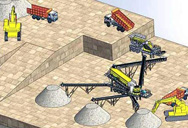

Cone Crushers; Typically, the initial crushing stage is completed using either gyratory crushers or jaw crushers. It is often the case that there will be only one crusher installed, and this will be referred to as the ‘Primary Crusher’. Cone crushers are typically used for 2 nd, 3 rd 4 th stage crushing steps (although not always).

Read More

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017.3.4 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5] crusher [4] The tie rod and compression spring ensure that the ...

Read More

MCC Series Cone Crusher Minyu Machinery Corp.

2023.8.7 MCC Cone Crusher. There are generally four types of Standard Cone Crushers: the MCC Standard or Coarse type, the MCF Fine or Medium type, the MCS Short Head type MCSS Super Fine type. All

Read More

Raptor® Cone Crushers for Mining and Aggregate

2023.12.19 Raptor® cone crushers 3 Reliable: Rock solid performance. Our Raptor cone crusher spare parts are designed to offer . excellent performance with increased durability, smoother . operation and reduced maintenance expenses. We keep your essential equipment running. Structural Integrity. The critical load bearing components of

Read More

2. GYRATORY CRUSHERS - Metallurgist Mineral

2017.4.19 The original patent for the gyratory crusher was granted to Phile- tus W. Gates in 1881. This fint crusher was used by the Buffalo Cement Co. At the time these early gyratory crushers were developed ... surface of an acute cone, the apex of which is within the spider. The amplitude of the base is determined by the eccentric. The gyrating

Read More

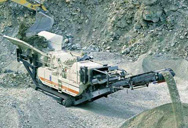

Mobile Cone Crushers, Sandvik Mobile Cone Crusher Series

Tracked cone crushers. We understand your exacting aggregate product quality demands; Sandvik Hydrocone and S-type gyratory mobile cone crusher series can help you meet the challenges you face on a daily basis. Our mobile cone crushers are ideal for providing you the highest quality end products to maximize your bottom line.

Read More

Gyratory Crusher - an overview ScienceDirect Topics

Gyratory and Cone Crusher. In Mineral Processing Design and Operations (Second Edition), 2016. 5.1 Introduction. Gyratory crushers were invented by Charles Brown in 1877 and developed by Gates around 1881 and were referred to as a Gates crusher [1].The smaller form is described as a cone crusher. The larger crushers are normally known as primary

Read More

QH332 Cone crusher - SRP

214 mm (8 in.) Sandvik QH332 is a tracked, self-contained cone crusher designed for versatility, safety and high performance. Featuring the Sandvik Hydrocone crusher, it comes with a number of features to ensure maximum uptime and minimum operator intervention. QH332. Features. Product data. Images. Additional product information.

Read More

Cone Crusher at Best Price in India - India Business Directory

View Mobile Number. Contact Supplier Request a quote. Roljack Cast Steel Cone Crusher ₹ 50,00,000. Get Quote. Mild Steel Roljack Rsc210 Automatic Cone Crusher ₹ 68,00,000. Get Quote. Roljack Rsc200 Cone Crusher, Automatic Grade: Automatic ₹ 65,00,000. Get Quote.

Read More

3 Types Of Discharge Adjustment Devices For Cone Crushers - ZENITH Crusher

2021.6.15 The output size of cone crusher is determined by the distance between mantle and concave. But many people don’t know much about the discharge adjustment dvice of cone crusher. Here, we introduce 3 types of discharge adjustment devices for cone crushers: fixed pulley, hydraulic pusher, and hydraulic motor.

Read More

Spare/replacement parts for cone crushers - FLSmidth

Key Benefits. Our cone crusher spare parts are more durable, reliable and are improved over OEM standards. Excel spare parts have a longer wear life and improved efficiency and throughput. Our parts are used in Omnicone, Symons, Metso, MP, HP, GP series, Sandvik and Nordberg crushers.

Read More

Trio® Crushing Equipment Weir

The reduction ratio of a horizontal impact crusher is much higher than that of a jaw or cone crusher. The Trio® APP series is the larger of the two crushers and is used for primary stage crushing of larger feed sizes. It is a very versatile machine, but does not produce as fine a product as the Trio® APS series. ...

Read More

Sandvik Hydrocone Superior Replacement Parts

Real Crusher Parts Factory Based In China. Yeco was found in 2004 and has been focusing on ensuring our crusher parts operates effectively throughout its life. For keeping the products high performance, Yeco is

Read More

Cone Crusher Parts - 911 Metallurgist

2017.2.19 Cone Crusher MANTLE. The Mantalloy head mantle of this cone crusher is a replaceable wearing surface. It is made of alloyed manganese steel, and is held in place with a self-tightening head nut. On

Read More

HAZEMAG CYBAS-i Cones High Performance Cone Crusher

2022.7.6 HAZEMAG cone crushers are available in a capacity range of 100 – 1500 short ton/hour depending on the machine selection and feed sizes up to approximately 20 inch slabs. The CYBAS-i. CONE. High Performance Cone Crusher. The CYBAS-i. Cone crusher is a modern high performance hydraulically adjusted (hydroset-type) cone

Read More

Cone Crusher Liners: How to Select and When to Change

2020.6.23 90-100% passing the closed-side feed opening. Some people look at 80% of the open side as well and select the smaller of the two. 40-60% passing the midpoint. 0-10% passing the closed-side setting. A well-graded feed to the Cone Crusher. You want to match the entire feed gradation, not just the feed size, so that you utilize the entire chamber.

Read More

Trio® TC Series Cone Crusher Weir

The Trio® TC Series cone crusher is designed for tough secondary and tertiary crushing including pebble crushing applications. Within the mining industry, this crusher is frequently used to process precious metals and a wide spectrum of other minerals. In the aggregates industry, it's typically used for feed materials such as river pebbles ...

Read More

TRIO TC SERIES CONE CRUSHERS - Diamond Equip

2016.8.13 TC series cone crushers incorporate a heavy duty design. TRIO Cone crushers have large cone head diameters, which allow a medium-speed increase to equal the linear velocity and processing capacity of high-speed crushers in the market. Operating at medium-speed, TRIO’s larger socket assembly provides full support under both

Read More

auto greasing systems for hydro ne crusher patent

Ашигласан Hydro Cone Crusher friedelsofteu. auto greasing systems for hydro cone crusher patent auto greasing systems for hydro cone crusher patent; Leave a Reply 05May Cone Crushers HP Series Cone Crushers system with a fixed return point makes sure that the crusher setting is instantaneously maintained even after auto greasing system ...

Read More

Cone Crushers – MEKA

Just call +90-312-397-91-33 and we will help you in any way we can. You can also send an e-mail to sales@mekaglobal, or fill in the inquiry form if you would like to pass us a detailed inquiry or project information. Use the Call Back option if you would like to be contacted by our sales team. CALL BACK INQUIRE NOW. MEKA cone crushers are ...

Read More

Gyratory Crusher Cone Crusher Mantle Differences - 911

2015.7.25 In the Gyratory all the movement is in the bottom of the crusher mantle. This is due to the angle that the main shaft is on. The greater angle of the cone crusher puts the pivot point below the distributor plate. While the pivot point for the gyratory crusher is at the spider cap. This difference in the pattern of gyration has a purpose.

Read More