Crusher, Crusher Equipment, Crusher Machine, Crushers for

2024.1.23 PF Series Impact Crusher. Thousands of Zenith PF Series Impact Crushers are installed all over the world in recent 20 years. It has been proved that this

Read More

Stone Crusher, Stone Crushing Equipment, Export Stone

2024.1.22 ZENITH's stone crusher is designed to achieve larger productivity and higher crushing ratio. From large primary crushers jaw crushers and impact crushers to

Read More

PF Impact Crusher - ZENITH Crusher

2023.12.28 PF Impact Crusher. PF Impact Crusher makes use of impact energy to crush materials. It’s used as a secondary crusher in stone crushing plants. Longer Service Life. Easier Maintenance. Adjustable

Read More

What is an Impact Crusher? - ZENITH Crusher

5 天之前 Impact crusher machines are available as stationary, track, or mobile units, and can be used in the primary, secondary, or tertiary position in the Producer’s line up. Impact crushers can be subject to high wear

Read More

Trio® Crushing Equipment Weir

Our range of Trio® vertical shaft impactors (or ""vertical impact crushers"") are engineered to produce high-quality, well-shaped particles and fine aggregates. They deliver outstanding

Read More

Optimization of key components of impact crusher based on

Inspired by the bionic wear-resistant structure, the shape and parameters of an impact crusher chamber are optimized. Taking both crusher strength and crushing effect into

Read More

Load and wear experiments on the impact hammer of a

2015.11.1 Impact hammers are important components of impact crushers, and are often shortlived due to the high-impact nature of their use. Wear-resistant alloys are

Read More

Types of Crushers: What You Need to Know - Machinery

Hammer mills and impact crushers. One of the most versatile crushers available, hammer mills and impactors can be primary, secondary, and tertiary crushers. Hammer mill crushers use continuous hammer blows to shatter and disintegrate material. They are typically horizontal rotating in an enclosed cylinder casing. The hammers are attached to a ...

Read More

Crushing 101 – Different types of crushers for distinctive needs

2020.12.17 Jaw crushers can be divided into two basic types, single and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation, along with the toggle plate, causes a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of ...

Read More

Simulation of particle flows and breakage in crushers using ...

摘要:. DEM simulation using a breakage model is applied to study a broad range of existing impact based crushers to better understand machine level operation and to demonstrate that such modelling is now possible. Predictions for a range of types of hammer mills, vertical and horizontal shaft impactors are presented.

Read More

[Minecraft][2B2T]Impact Client 4.9.1 - 1.12.2 功能翻译 - 哔 ...

2022.8.29 如何调试Impact 4.9.1 - 1.12.2 功能 以下内容 非机翻/抄袭!都是 UP个人手动翻译的!Impact Client 4.9.1 功能翻译 By Mercyzz_ Combat 战斗类 Aimbot 辅助瞄准(玩家/生物) Anti Bot Bypass服务器Anti-Cheat检测 (Bypass AAC/NCP插件 ...

Read More

The Ultimate Guide to Impact Crusher Blow Bars - AGICO

2023.2.21 Each type operates on a different principle, but the basic working principle is the same. Horizontal shaft impact crushers have a horizontal axis of rotation and use a blow bar that is fixed on the rotor. Vertical shaft impact crushers have a vertical axis of rotation and use a different type of blow bar that is more suitable for softer materials.

Read More

Impact crusher structure, working principle and features

2021.9.2 1.1 Impact crushers can be divided into two types according to the number of rotors: single-rotor and double-rotor impact crushers. 1.2 The structure of the single rotor impact crusher (Figure 1) is relatively simple and consists mainly of the rotor 5 (strike plate 4), the impact plate 7 and the machine body. The rotor is fixed to the main shaft.

Read More

Simulation of particle flows and breakage in crushers using

2015.4.1 DEM with a particle breakage model has been used to successfully model crushers. • Impact crushers such as hammer mills, VSI and HIS have been simulated. • Energy absorbed determines breakage with geometric rules for progeny generation. • Predictions include power draw, liner stresses and wear, product size and throughput. •

Read More

Nordberg® NP Series™ Horizontal shaft impact (HSI)

2023.7.20 Nordberg® NP Series™ HSI crushers consist of heavy rotor, wear resistant materials, and an optimal crushing chamber design. This combination has proven revolutionary in improving capacity and product quality, as well as in reducing operating and wear costs. Nordberg® NP™ crushers have a unique blow bar attachment system.

Read More

Modelling and simulation of particle breakage in impact crushers

2004.12.10 Section snippets Mass balance. Recall the size distribution model for crushers developed by Whiten (1972) and shown in Fig. 1. The particles are characterized by their size distribution that is represented in a discrete form by the vectors f (feed) and p (product), respectively. Each component of f and p represents the mass fraction of the

Read More

Impact - MC百科最大的Minecraft中文MOD百科

模组Impact的介绍页,我的世界MOD百科,提供Minecraft(我的世界)MOD(模组)物品资料介绍教程攻略和MOD下载。概述 Impact 是一个黑客端,带有 Baritone ,和许多作弊功能。但有一部分功能在 Mod 版无法使用,仅限于作弊端。

Read More

Stone Crushers: A Technical Review on Significant Part of

2022.5.14 Impact crushers are most commonly used in stone quarrying industry for making fine-grained stones used in road and building materials. The impact crusher as shown in Fig. 6 feed the material into the crushing chamber where a rotating disc containing hammer is working. The rotating action of the hammer apply heavy blow over the feed

Read More

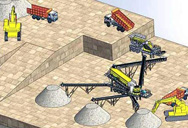

Crusher, stone crusher, aggregate processing

5 天之前 Stationary Crushing Plants. These cases of stationary crushing plants may be the same with your demands, so they are good references. View More; Mobile Crushing Plant. The cases of mobile crushing plants

Read More

Impact Crusher Working Principle - 911 Metallurgist

2015.6.23 Impact crushing crushing is the reduction of materials by rubbing; primarily a grinding method. Shear crushing is accomplished by breaking along or across lines of cleavage. It is possible, when required,

Read More

Simulation of particle flows and breakage in crushers using

2015.4.1 DOI: 10.1016/J.MINENG.2014.11.017 Corpus ID: 109850935; Simulation of particle flows and breakage in crushers using DEM: Part 2 – Impact crushers @article{Sinnott2015SimulationOP, title={Simulation of particle flows and breakage in crushers using DEM: Part 2 – Impact crushers}, author={Matthew D. Sinnott and Paul W.

Read More

Modelling of output and power consumption in vertical shaft impact crushers

2008.8.1 Abstract. The vertical shaft impact (VSI) crusher is a commonly-used machine in aggregate production. A comprehensive understanding of the physical phenomena that influence the power consumption and the particle output of the device are essential to enable development of protocols that minimize energy consumption during

Read More

Simulation of particle flows and breakage in crushers using

2015.4.1 To date there has been only very limited use of DEM to analyse impact crushers. Most examples of such DEM models either ignore the breakage and therefore only consider the flow of material and some aspects of energy transfer inside crushers (Kostek, 2009, da Cunha et al., 2013) or only consider breakage for single particle impacts, such

Read More

How to Do Skull Crushers with Perfect Form - Shape

2022.12.6 B. Extend arms toward the ceiling above chest, palms facing each other. Engage glutes and core and pull the rib cage down to prevent low back from arching. C. Tucking elbows in and pressing shoulders down, slowly bend elbows to lower the dumbbells until they hover an inch above head or on either side of head.

Read More

Modelling and simulation of particle breakage in impact

Keywords: impact crushing; standard matrix representation; Weibull cumulative distribution 1. Introduction During the past few decades, impact crushers have become widely used machines for comminution

Read More

A performance model for impact crushers - ScienceDirect

2002.10.1 Abstract. In this paper we develop a performance model for impact crushers. The product size distribution is obtained as a function of the crusher’s rotor radius and angular velocity, the feed rate and the feed size distribution. The model is based on the standard matrix formulation that includes classification and breakage matrices.

Read More

mn/Хацрын бутлуурын мэдээллийн хуудас диаграм.md at

Contribute to sbmboy/mn development by creating an account on GitHub.

Read More

Everything you need to know about Crushers in Cement

The roller crushers are used for moist and sticky materials. Generally the machines have to be rigid enough to crush also hard inclusions. As the reduction ratio is only about 5:1 a 2-stage crushing is required in most applications. Fast running type crushers like hammer and impact crushers are the simplest and cheapest solution, whenever the ...

Read More

How Impact Crushers Work: A Comprehensive

2023.3.11 Crushing Equipment / March 11, 2023 / 5 minutes of reading. An impact crusher is a machine used to crush materials by impact energy. It works by feeding the material into a rotating rotor, which is

Read More

Optimal energy control of a crushing process based on vertical shaft ...

2016.1.15 The technology of VSI crushers is based on impact breaking action using the rotor kinetic energy while in cone crushers, for instance, the rock is broken by compression action. Another important feature that makes the VSI crusher to be technologically efficient is the cascade flow or bi-flow [1] option. This is defined as a

Read More

Modelling of output and power consumption in vertical shaft impact ...

DOI: 10.1016/J.MINPRO.2008.04.005 Corpus ID: 108433716; Modelling of output and power consumption in vertical shaft impact crushers @article{Bengtsson2008ModellingOO, title={Modelling of output and power consumption in vertical shaft impact crushers}, author={Magnus Lars Bengtsson and Carl Magnus Evertsson}, journal={International

Read More

Trio® Crushing Equipment Weir

These crushers produce high-quality aggregates at a high production rate. The reduction ratio of a horizontal impact crusher is much higher than that of a jaw or cone crusher. The Trio® APP series is the larger of the two crushers and is used for primary stage crushing of larger feed sizes.

Read More

Understanding the Different Types of Crushers Agg-Net

2018.9.10 Impact crushers tend to be used where shape is a critical requirement and the feed material is not very abrasive. The crushing action of an impact crusher breaks a rock along its natural cleavage planes, giving rise to better product quality in terms of shape. The quality of these products makes them ideal for use in highly specified roadstone ...

Read More

Barmac® B Series™ impact crushers - Metso

Barmac® vertical shaft impact (VSI) crushers were the first vertical shaft impactors in the world. The original Barmac® was developed in New Zealand over 40 years ago after which the VSI crushers have spread to thousands of crushing sites around the globe. Barmac® crushers have evolved immensely over the years, but their trademark is still ...

Read More

A fundamental model of an industrial-scale jaw crusher

2017.5.1 Abstract. In this study, an analytical perspective is used to develop a fundamental model of a jaw crusher. Previously, jaw crushers were modelled in regard to certain aspects, for example, energy consumption (Legendre and Zevenhoven, 2014) or kinematics (Oduori et al., 2015). Approaches to date have been mainly property specific.

Read More

Horizontal Shaft Impactors - Astec

2024.1.20 Horizontal shaft impactors (HSI) offer the adaptability and capacity required to meet producer expectations. With three- or four-bar configurations, large feed opening and high-performance MPR rotor, Astec impact crushers are well-suited for a variety of applications. With 30% more uptime and 25% more production than

Read More

(PDF) INVESTIGATION OF ROCK AGGREGATE QUALITY

2021.12.3 Concerning cone and vertical shaft impact crushers, rock aggregate quality was investigated for products with a particle size range of 33-63 mm. As a result of full-scale crushing tests, it was ...

Read More