Talc Powder Grinding Plant in Sudan - sbm-mill

2023.3.30 Talc Powder Grinding Plant in Sudan. Material: talc. Model: MTW175. Capacity: 13-15TPH. Final Product Size: 200-400mesh. Location: Khartoum North, Sudan. Case study. Sudan's climate is tropical. There is hardly any rainfall. So building factories

Read More

15TPH Talc Grinding Plant

2023.10.11 Sudan's climate is tropical. There is hardly any rainfall. So building factories in Sudan requires stable and durable equipment. This customer wanted to build

Read More

Talc Powder Grinding Plant in Sudan - sbm-mill

2023.3.30 Sudan's climate is tropical. There is hardly any rainfall. So building factories in Sudan requires stable and durable equipment. This customer wanted to build

Read More

Sudan's Talcum Powder Market Report 2024 - Prices, Size

2024.1.6 Talcum Powder Exports Exports from Sudan In 2022, after ten years of growth, there was significant decline in overseas shipments of talcum powder and other

Read More

Talc - Hosokawa Alpine

The Kompaktor is designed for the de-aeration of talc (densification). A high bulk density without creation of hard spots will be achieved during the densification process. The

Read More

JJ Talc Global Supply Chain Research Brief - Breast

2020.10.7 Three mines (in China, India, and Brazil) provide the talc used by JJ worldwide. This brief identifies the flow of raw talc from the mines to four mills that grind

Read More

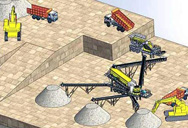

Talc processing plant, line, talc crushing and grinding

2023.1.19 From talc rock to talc powder, the talc processing plant involves crushing, washing, sorting, analysis, milling (grinding, pulverizing) and packing etc. Services

Read More

Talc Processing Plant, Talc Crushing and Grinding Equipment

2024.1.8 Talc Processing Technology. 1.Crushing Stage:Big blocks would be crushed into materials within 15mm-50mm--- the feeding size of grinders. 2.Grinding Stage:The

Read More

Minerals Potential and Resources in Sudan - UNCTAD

2020.9.10 the boundaries between nine countries Sudan has a huge mineral potential yet to be evaluated and developed. • The Ministry of Minerals, through the Geological

Read More

Talc peocessing equipment for sale - unisbm

Talc Processing Plant From talc rock to talc powder, the talc processing process involves mining, washing, sorting, analysis, milling (grinding, pulverizing) and packing etc. SBM

Read More

Improved flotation of molybdenite from talc using a

2022.1.1 The rate of increase became very slow after 3 min, and the recovery increased by only 5% in 3–10 min. At the same time, when the flotation time is within 10 min, the recovery of talc is always less than 10%. Therefore, for the reagent system of this work, 3 min is the most efficient and preferred flotation time.

Read More

Effect of particle shape and roughness of talc mineral

2004.2.16 Talc mineral having 59.2% SiO 2 and 30.97% MgO from Turkey was used in this study (Table 1). The chemical analysis of the sample indicated that the sample was pure enough for this study as the shape may also be influenced by the particle mineral composition. Grinding tests. All of the grinding tests were performed in dry conditions.

Read More

powder mill in Sudan - stone-pulverizer

2019.4.23 LUM Series Superfine Vertical Roller Grinding Mill is widely used to process the superfine dry powder. It can be widely used in attapulgite, bentonite, calcite, limestone, GCC, talc, barite, dolomite and other non-metallic mineral ultra-fine powder processing, is the first choice of Large-scale construction of non-metallic mineral grinding....

Read More

Safe Ground Spices — Vikaspedia

Turmeric powder: Addition of lead chromate, mentanil yellow, chalk powder or yellow soap stone powder and starch: substitution with other rhizomes e.g. arrrow root etc. 03: Chillies powder: Addition of brick powder, salt powder or talc powder, artificial colours and dyes, colour, grit, sand, dirt, filth, saw dust, dried tomato skin: 04 ...

Read More

Insta-Pro Soybean Dehulling - How Does it Work?

2012.9.20 Dehulling (or decortication) is the process of removing the hull of a seed and can be applicable to more than just soybeans. Typically, a producer wishes to decrease the final fiber content in the end product, so dehulling is the answer. To start, the seeds should have a moisture content of about 10%. This dryness allows the beans to be

Read More

powder grinding mill in Sudan - stone-pulverizer

2019.4.23 Talc Powder Grinding Plant in Sudan - sbm-mill. Talc Powder Grinding Plant in Sudan. Material: talc. Model: MTW175. Capacity: 13-15TPH. Final Product Size: 200-400mesh. Location: Khartoum North, Sudan. Case study. Sudan's climate is tropical. There is hardly any rainfall. So building factories in Sudan requires stable and

Read More

Talc Properties, Formation, Occurrence and Uses Area

2023.8.25 Talc. Talc is a naturally occurring mineral known for its softness, smoothness, and ability to absorb moisture. It is a silicate mineral that is composed of magnesium, silicon, and oxygen. Talc has a unique combination of properties that make it useful in a variety of industrial and consumer applications. Talc’s chemical formula is

Read More

Talc as Reinforcing Filler in Polypropylene Compounds:

2017.7.1 Talc has a positive effect on the stiffness but a deleterious effect on the tensile strength and ductility; 4. Plately fillers such as talc are likely to suffer more severely from the effect of stress concentration. As results, the impact strength and the resistance of crack propagation were decreased; 5.

Read More

Effect of Particle Shape and Roughness of Talc Mineral

2004.2.1 In addition to the grinding time, while the roundness of particles was found to be 0.739 for 0.34 U values (powder/grinding medium rate), it increased to 0.788 when the U value was adjusted to 0.67.

Read More

Talc Stone Mill And Talc Powder Making Process

2023.2.17 In general, the grinding process can be broken down into the following steps: 1. Crushing: The raw talc is first crushed into smaller pieces using a jaw crusher, cone crusher, or impact crusher. 2. Grinding: The crushed talc pieces are then ground into talc powder using a ball mill, hammer mill, jet mill, or roller mill.

Read More

The application of talc powder in plastics- Qingdao EPIC Powder

2022.1.7 The application of talc powder in plastics. As an additive, modifier, or filler, talc powder has been widely used in papermaking, paint, coatings, ceramics, chemicals for daily use, plastics, food, medicine, and other industries. Talc has the properties of soft texture, easy-grinding, high gloss, low oil absorption, and good transparency.

Read More

Exposure Data - Carbon Black, Titanium Dioxide, and Talc

Exposures to total dust were found to range from 5.4 to 199 mg/m as measured by phase-contrast optical microscopy ( Dement Shuler, 1972. reported on commercial cosmetic-grade talc (baby and body talcum powder) used in Pakistan between 2000 and 2004. Sixty samples were analysed using atomic absorption techniques, X-ray diffraction, polarized ...

Read More

Dispersion of kaolinite and talc in aqueous solution: nano

2002.4.1 One such treatment is to dry grind talc for short periods of time. The effects of extensive dry grinding on the structure of talc have been studied by Aglietti (1994), Sanchez-Soto et al. (1997) and Zajac and Malandrini (1997). These studies conclude that mechano-chemical effects, including amorphisation, occur during grinding.

Read More

Method for manufacturing talc powder - Google Patents

2007.10.31 The temperature of calcination of talc powder is 1300-1600 ℃; Calcination time: determine according to the thermal value of coke and talcum grain etc.; Talcous order number is the 800-1000 order; Coupling agent accounts for talcous 1-5%, adds 30 times in water, sprays, floods talcum powder, and dipping time is 48 hours; In

Read More

Talcum Powder Manufacturing Plant - Adinath International

2024.1.1 S.P. Ring Road, Nikol, Ahmedabad, Gujarat, India-382350. Adinath International is one of leading talcum powder manufacturing plant manufacturer in India. Our state-of-art body talc powder production plant is a combination of various machines to make the entire body talc production process a breeze. As a trusted exporter of talc powder ...

Read More

Classifier Mills - Hosokawa Alpine

ACM. Classifier Mill. To the machine. The ACM classifier mill is suitable for the comminution of numerous products and is employed in every branch of industry. It is also suitable for the fine and ultrafine grinding of soft to medium-hard products.

Read More

Talcum powder manufacturing process PDF - SlideShare

2013.4.24 Raymond mill for talc: Raymond mill can be used for grinding talc into powder less than .044mm. The entire talc grinding plant includes jaw crusher, elevator, vibrating feeder, classifier, collector cloth deduster and-pressure blower. Ultrafine grinding mill for fine talc powder: The fine talc powder is generally 1250 mesh, 2500mesh, and

Read More

Talc Processing Equipment, Process Flow, Cases - JXSC

2019.8.23 Description. The term talc refers both to the pure mineral and a wide variety of soft, talc-containing rocks that are mined and utilized for a variety of applications. Talc forms mica-like flakes. Talc is the softest mineral on the Mohs hardness scale at 1 and can be easily cut and crushed. Talc has perfect cleavage in one direction.

Read More

Crushed Rock Fine Powder Grinding Machine - Crusher Mills

Limestone grinding mill,limestone powder milling machine . It is the key equipment used for grinding crushed stone materials into powder in . Ultrafine grinding mill is the ultra fine ground limestone powder making machine.

Read More

20tph talcum powder processing plant - LinkedIn

2023.3.23 A talcum powder processing plant with a capacity of 20 tons per hour (tph) is a significant undertaking that requires careful planning and execution. The plant must be designed and constructed to ...

Read More

Talc - Minerals - Applications Hamburg Dresdner

Talc grinding. Talc is a soft clay mineral with a Mohs hardness of 1. Chemically talc consists of hydrated magnesium silicate and it is won in mines all over the world. Broken chunks of talc from the mining plant are

Read More

Classifiers Air Classifiers - Hosokawa Alpine

Toner and pigment separation and dedusting of powder coating containing titanium dioxide: We developed our TSP and TTSP ultra-fine classifiers for this demanding application. For oil crops and precious metals: The

Read More

10 Best Ore Beneficiation Plants for Sale (with Costs)

2021.3.24 38%. Recovery rate. 74%. Manganese beneficiation machines: GZD-850×3000 vibrating feeder,PE-500×750 jaw crusher,Φ1200 cone crusher,B500x10 m belt conveyor, 2YK1535 inclined vibrating screen,Ф2700×4500 ball mill, High-strength Magnetic drum separators. 07 150 TPH Bauxite ore beneficiation plant in Indonesia.

Read More

TALCUM POWDER A VALUE ADDED PRODUCT OF TALC

2023.7.6 TALCUM POWDER A VALUE ADDED PRODUCT OF TALC Page 4 of 21 CHAPTER 2 WORLD MARKET OF TALCUM POWDER (330491) Due to the COVID-19 pandemic and Russia-Ukraine War Influence, the global market for Talc Powder estimated at USD 2.28 billion in the year 2022, is projected to reach a revised size of USD

Read More

Emerging techniques for adulterant authentication in spices

2021.9.1 The ESA and ASTA set 1% and 0.5–1% w/w maximum level of adulterant in spices. Ground spices are more prone to adulteration because during milling and grinding the shape of both the spice and adulterant becomes a fine powder, which makes it difficult to detect the adulterants in the final produce.

Read More

Emerging techniques for adulterant authentication in spices

2021.9.1 SI. No. Type of spice Name of the spice Adulterants used Effects on humans; 1. Seed: Cumin (Cuminum cyminum) and black cumin (Nigella sativa): Grass seed coated with charcoal dust a, White cumin fennel seed covered with marble dust a, peanut butter powder/shell c: Anaphylaxis c: Coriander (Coriandrum sativum): Whole: plant

Read More

Superfine Powder Grinding Plant For Micron Silicon Powder

2023.12.22 Our superfine powder grinding plant, or ultrafine powder grinding plant, is a kind of dry ball mill grinding system with air classifier which forms a complete grinding circuit, so the oversizes ...

Read More

talcum powder manufacturing process - LinkedIn

2023.2.24 Talcum powder, also known as talc powder, is a soft white powdery substance made from talc mineral. Talc is a naturally occurring mineral that is mined from the earth and is composed of magnesium ...

Read More

Spiral Jet Mills and - hosokawa-alpine

Jet mills (also called air jet mills) have a special feature: they do not need mechanical grinding tools. Instead, the particles are crushed and ground in a gas stream by repeatedly colliding with each other there. Jet mills are an excellent choice in industry when ultra-fine grinding is required. They are suitable for dry and very hard ...

Read More